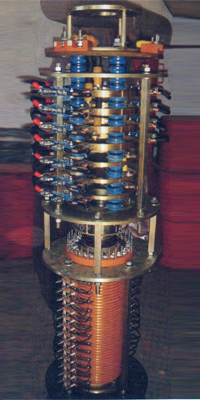

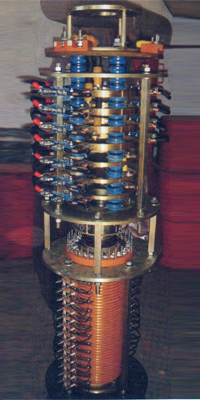

Center Collector

Center Collector

On the transmission-type collectors

Under the transmission-type collectors

Uses

Center collector currents from fixed equipment can be sent to rotating devices, mainly in various types of gantry crane, fixed crane is used to make circular motion relative parts of power transmission and new transmission numbers.Using standard

IEC 60204-32: 1998 《Lifting Electric technical conditions》GB 14048.1 《Low-voltage switchgear and control equipment General》

JT / T 70.2-93 《Port Crane Electric Control Equipment and technical conditions a set of electrical appliances》

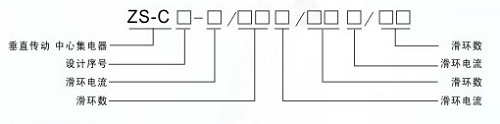

Product line and model description

This product is more than the next type of transmission mode control loop formed with the series, to the ring current capacity and the number of sub-standard loop.

Product dimensions and installation dimensions

- On the transmission-type collectors

C2C4 Overall height L=632+A+B

A=12C+61

B=56a+28b+48+(28)

C61 Overall height L=56a+28b+385+(28)

Including: a number of large slip-ring, b

is the number of slip-ring

c for small slip-ring number,

When b> 0 End of 28 service hours and

- Under the transmission-type collectors

C2C4 Overall height L=543+A+B

A=12C+54

B=56a+28b+48+(28)

C62 Overall height L=56a+28b+430+(28)

Including: a number of large slip-ring, b

is the number of slip-ring

c for small slip-ring number,

When b> 0 End of 28 service hours and

Critical dimensions and ring current rating table

| Transmission | Type | threading aperture A | threading aperture B | Dimension C | transmission claw diameter D | slip ring current rating | |||

| Under the transmission | ZS-C61 | Φ140 | Φ380 | Φ200 | — | — | 400A | 63A | — |

| ZS-C1 | Φ140 | Φ380 | Φ200 | — | — | 400A | 63A | 10A | |

| ZS-C3 | Φ190 | Φ450 | Φ260 | 630A | 630A | — | 63A | 10A | |

| On the transmission | ZS-C62 | Φ140 | Φ380 | Φ230 | — | — | 400A | 63A | — |

| ZS-C2 | Φ140 | Φ380 | Φ230 | — | — | 400A | 63A | 10A | |

| ZS-C4 | Φ190 | Φ450 | Φ260 | 630A | 630A | — | 63A | 10A | |

Brush, wire configuration table

| slip ring type | single-loop carrying current (A) | configuration wire cross-sectional area (mm) 2 | configuration Brush quantity (right) |

| Great slip-ring | 630 | 150 or 2×75 | 4 |

| 400 | 120 | 3 | |

| Middle slip-ring | 63 | 16 | 2 |

| Small slip-ring | 10 | 25 | 1 |

The number of n values of the table slip ring

|

ZS-C1 | ZS-C2 | ZS-C3 | ZS-C4 | ZS-C61 | ZS-C62 |

| 630A | — | — | 1-60 | 1-60 | — | — |

| 400A | 1-60 | 1-60 | — | — | 1-60 | 1-60 |

| 63A | 1-60 | 1-60 | 1-60 | 1-60 | 1-60 | 1-60 |

| 10A | 1-60 | 1-60 | 1-60 | — | — |

Maintenance

Center collector should be mounted vertically, the drive disk bump should be properly installed on the crane in the drive groove. Center collector axis of rotation on the crane rotation axis coincide, allowing deviation is less than the total electrical center assembly with high 1 / 1000.

center collector should be checked before using the line terminal is pressed, carbon brush and slip ring contact is good, whether the card blocking phenomenon.

should regularly check the carbon brush wear, clearly fallen off carbon brush wear powder, if necessary, replaced with new carbon brush. In the months between the moving parts into the butter.

center collector temporarily used, the environment should be kept dry.

Order Know

1, As the specific type installation and the required current rating of the ring and the corresponding rings

2, Whether or not to dual-loop parallel

3, Whether there are special requirements for wiring

4, Whether the cable wiring board, No. labeling requirements

5, Whether to increase the shielding shell

6, Asking Ship Survey

7, For high-pressure center will feature a mixture of electrical, special ordered upon request.